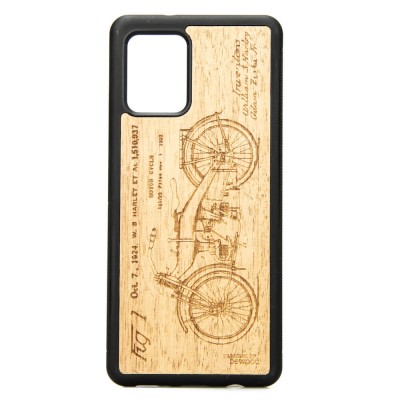

One of a kind - a few words about the production process.

We place the extracted piece of the topiary (more information about it in the text below) in a special container, then pour the dyed resin. The colors are combined before or only after pouring - depending on the effect you want to achieve. The liquid gets into all the crevices of the chevron, ultimately creating patterns - unique, sometimes mysterious and evoking all sorts of associations. The mold created in this way should be properly taken care of, at least to eliminate the risk of air bubbles. After some time, when the resin solidifies and the whole mold obtains its final, compact and hardened structure, you can proceed to the next stage, which is machine woodworking and laser cutting. Then a layer of ecological oil is applied to the carefully sanded surface of the wood with resin. After a few hours, the wood absorbs most of the oil, and any excess is removed with a cloth. The final step is polishing - gently, to achieve an elegant satin surface of the case.

Discarded, unnecessary pieces of wood - a second life.

To create a case that is a combination of resin and wood, properly crafted pieces of wood are needed. All Unique's designs are a synthesis of chance, invention and, above all, nature, specifically, wood in the form of a chevet, which are actually unwanted swellings of the tree trunk. Elements with such deformations are immediately rejected for the furniture industry or musical instrument manufacturing. What is bad for the industry and not necessarily good for the tree itself turns out to be an extremely interesting raw material for further processing in the case of creating unique phone cases. This is because the wood of the chitchat immediately catches the eye with its richness of shape and unique structure.